Client industry: Petrochemical.

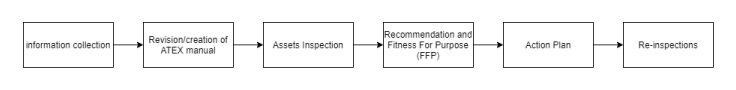

ATEX inspections, whether according to European or American standards, follow clear and mandatory rules. The ATEX applies to all industries that operate with flammable products or with risk of explosiveness.

The manual creation or revision involves many documentary collection and asset inspections in their operational context.

The explosiveness manual is the installation baseline. After the creation of the baseline, the inspection of all equipment in classified areas begins. The inspection process requires that all relevant existing documentation be organized by equipment and can be accessed by the inspectors on the shop floor during the inspections.

All non-conformities or improvement found, must be analysed so that actions and their priority can be defined. A fitness for purpose (FFP) analysis may occur.

After the definition of actions and their implementation, is necessary to carry out re-inspections to verify the effectiveness of the actions.

After the initial inspection is done (inspection baseline), the periodic inspection should start.

The periodic inspections have their frequency defined by the regulations and consider the results of previous inspections. Is necessary to have an asset history that can be accessed easily and in multi-devices.

EQS digital has developed a set of digital tools that allow a full process digitizing, mitigation of data siles, ensuring communication throw stakeholders and validation to recognized gaps between what is defined in the manual and what is installed.

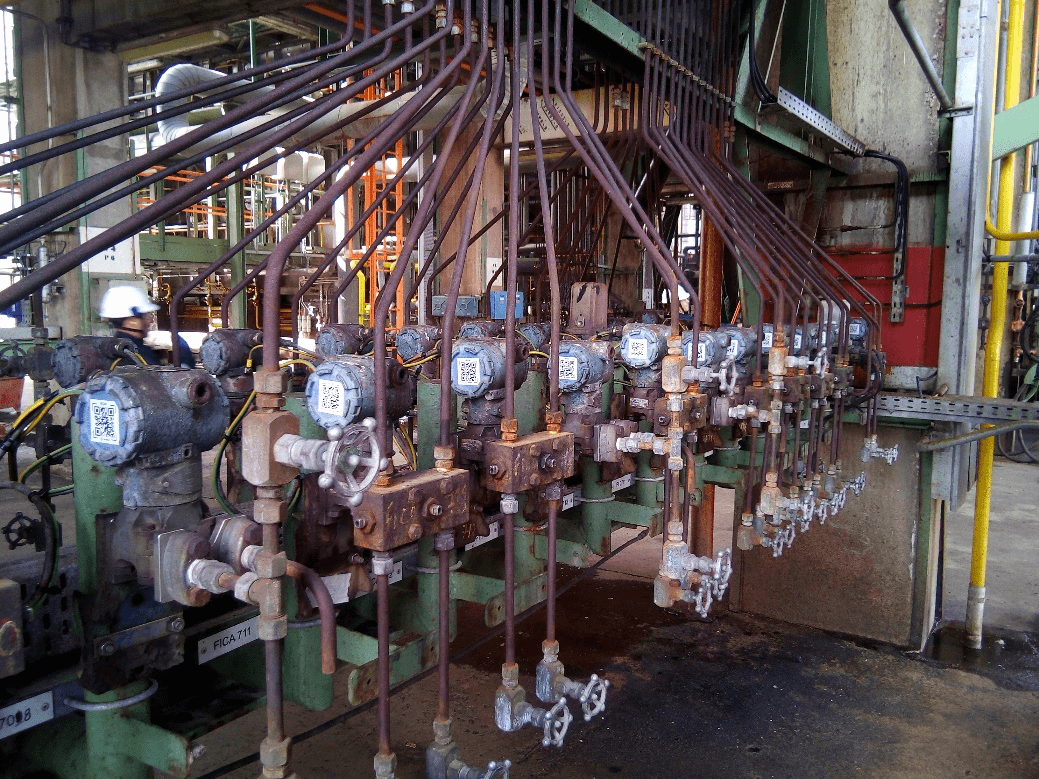

EQS Digital’s digital tools allow the digitization of all assets, whether in documentary terms, state of conservation, places where they are installed, all with real-time indicators.

All assets can be identified through smart tags, which guarantee that we are looking at the desired equipment and allow easy access to all information in the system.

The combination of the specialized services of EQS Global and the tools of EQS Digital we deliver an end-to-end service.